beer

BEER

HYSTORY OF BEER:

The origins of beer are older than recorded history, extending into the mythology of ancient civilizations. Beer, the oldest alcohol beverage, was discovered independently by most ancient cultures - the Babylonians, Assyrians, Egyptians, Hebrews, Africans, Chinese, Incas, Tautens, Saxons and the various wandering tribes that were found in Eurasia. These ancient peoples have left records to indicate they not only enjoyed their beer, but considered brewing to be a serious and important job.

In recorded history, Babylonian clay tablets more than 6,000 years old depict the brewing of beer and give detailed recipes. An extract from an ancient Chinese manuscript states that beer, or kiu as it was called, was known to the Chinese as early as the 23rd century BC. Beer was enjoyed by ancient peoples at all levels of society. Of course, some drank with more style than others. For example, the University of Pennsylvania Museum displays a golden straw used by Queen Shubad of Mesopotamia for sipping beer.

With the rise of commerce and the growth of cities during the Middle Ages, brewing became more than a household activity. Municipal brew houses were established, which eventually led to the formation of the brewing guilds. Commercial brewing on a significantly larger scale began around the 12th century in Germany.

Although native Americans had developed a form of beer, Europeans brought their own version with them to the New World. Beer enjoys the distinction of having come over on the Mayflower and, in fact, seems to have played a part in the Pilgrims decision to land at Plymouth Rock instead of farther south, as intended. A journal kept by one of the passengers - now in the Library of Congress - states, in an entry

from 1620, that the Mayflower landed at Plymouth because We could not now take time for further search or consideration, our victuals being much spent, especially our beer...

The first commercial brewery in America was founded in New Amsterdam (New York) in 1623. Many patriots owned their own breweries, among them Samuel Adams and William Penn. Thomas Jefferson was also interested in brewing and made beer at Monticello. George Washington even had his own brew house on the grounds of Mount Vernon, and his handwritten recipe for beer dated 1757 and taken

from his diary - is still preserved!

In recorded history, Babylonian clay tablets more than 6,000 years old depict the brewing of beer and give detailed recipes. An extract from an ancient Chinese manuscript states that beer, or kiu as it was called, was known to the Chinese as early as the 23rd century BC. Beer was enjoyed by ancient peoples at all levels of society. Of course, some drank with more style than others. For example, the University of Pennsylvania Museum displays a golden straw used by Queen Shubad of Mesopotamia for sipping beer.

With the rise of commerce and the growth of cities during the Middle Ages, brewing became more than a household activity. Municipal brew houses were established, which eventually led to the formation of the brewing guilds. Commercial brewing on a significantly larger scale began around the 12th century in Germany.

Although native Americans had developed a form of beer, Europeans brought their own version with them to the New World. Beer enjoys the distinction of having come over on the Mayflower and, in fact, seems to have played a part in the Pilgrims decision to land at Plymouth Rock instead of farther south, as intended. A journal kept by one of the passengers - now in the Library of Congress - states, in an entry

from 1620, that the Mayflower landed at Plymouth because We could not now take time for further search or consideration, our victuals being much spent, especially our beer...

The first commercial brewery in America was founded in New Amsterdam (New York) in 1623. Many patriots owned their own breweries, among them Samuel Adams and William Penn. Thomas Jefferson was also interested in brewing and made beer at Monticello. George Washington even had his own brew house on the grounds of Mount Vernon, and his handwritten recipe for beer dated 1757 and taken

from his diary - is still preserved!

ingredients

water- The water must be pure, with no trace of bacteria. This is vital, because it allows the other ingredients to release all their flavour. 95% of breweries have their own spring or natural well.

Barley

Hops: Hops or “green gold” come from a climbing plant with male and female flowers; only the female flowers are used. There are various varieties, ranging from very bitter to aromatic. Hops grew

Naturally in our regions in ancient times, and this plant has been used by brewers since time immemorial. In antiquity, it could be replaced by mixtures of aromatic herbs, in particular rosemary and thyme, which had the same preserving effect as hops but of course gave the resulting beverage a quite different flavour. Yes, it is hops that give beer its characteristic bitterness, and this plant became so successful that in the 18th century all varieties of beer contained hops.

hops from different countries

Eg. 'Hallertauer Mittelfrueh', 'Tettnanger', 'Spalter', and 'Saaz', golding, fuggle, buillion

Functions of hops

Clarification and preservation- more clarified is the beer, longer is the shelf life.

Imparts bitter taste.

Acts as an antiseptic, prevents it from bacterial attack.

Flavouring

Filter bed

Yeast: Yeasts transform the sugars in the must into alcohol and carbon dioxide. The type of yeast used varies according to the type of beer. There was a time when man had no control over yeasts in beer. Louis Pasteur was able to explain their role in the brewing process, and yeast culture was developed thanks to the work of the Danish scientist Hansen. Nowadays there are two main

varieties of yeasts that are used in brewing: saccharomyces cerevisiae and saccharomyces carlsbergensis (bottomfermenting).

Certain other products are used in the making of beer, in particular spices: coriander, ginger, cloves, sage, fennel, mustard seeds, aniseed, cinnamon, etc.

Barley

Hops: Hops or “green gold” come from a climbing plant with male and female flowers; only the female flowers are used. There are various varieties, ranging from very bitter to aromatic. Hops grew

Naturally in our regions in ancient times, and this plant has been used by brewers since time immemorial. In antiquity, it could be replaced by mixtures of aromatic herbs, in particular rosemary and thyme, which had the same preserving effect as hops but of course gave the resulting beverage a quite different flavour. Yes, it is hops that give beer its characteristic bitterness, and this plant became so successful that in the 18th century all varieties of beer contained hops.

hops from different countries

Eg. 'Hallertauer Mittelfrueh', 'Tettnanger', 'Spalter', and 'Saaz', golding, fuggle, buillion

Functions of hops

Clarification and preservation- more clarified is the beer, longer is the shelf life.

Imparts bitter taste.

Acts as an antiseptic, prevents it from bacterial attack.

Flavouring

Filter bed

Yeast: Yeasts transform the sugars in the must into alcohol and carbon dioxide. The type of yeast used varies according to the type of beer. There was a time when man had no control over yeasts in beer. Louis Pasteur was able to explain their role in the brewing process, and yeast culture was developed thanks to the work of the Danish scientist Hansen. Nowadays there are two main

varieties of yeasts that are used in brewing: saccharomyces cerevisiae and saccharomyces carlsbergensis (bottomfermenting).

Certain other products are used in the making of beer, in particular spices: coriander, ginger, cloves, sage, fennel, mustard seeds, aniseed, cinnamon, etc.

II. TYPES OF BEER

1. Lager

The word lager is derived from the German verb “lagern”, which means: to store. During the late middle ages, before the days of refrigeration, fermentation was a hit-or-miss affair, especially during the hot summer months. To ensure a supply of beer for the summer, brewers in the Bavarian Alps stored kegs of spring brew in icy mountain caves. As the beer slowly aged, the yeast settled, creating a drink that was dark but clear and sparkling with a crisper, more delicate flavour. In 1842, lager acquired its familiar golden colour when a brewery in Pilsen, Czechoslovakia perfected a pale, bottom-fermented version of the beer. Lagers typically take more time to brew and are aged longer than ales. Lagers are best enjoyed at cooler-than-room temperature.

2. Bock Beer

The other bottom-fermented beer is bock, named for the famous medieval German brewing town of Einbeck. Heavier than lager and darkened by high-coloured malts, bock is traditionally brewed in the winter for drinking during the spring.

3. Ale

Although the term covers a fascinating variety of styles, all ales share certain characteristics. Top-fermentation and the inclusion of more hops in the wort give these beers a distinctive fruitiness, acidity and a pleasantly-bitter seasoning. All ales typically take less time to brew and age then lagers and have a more assertive, individual personality, though their alcoholic strength may be the same. Ales are best enjoyed at room temperature or slightly warmer.

4. Porter and Stout

Whether dry or sweet, flavoured with roasted malt barley, oats or certain sugars, stouts and porters are characterized by darkness and depth. Both types of beer are delicious with hearty meat stews and surprisingly good with shellfish. The pairing of oysters and stout has long been acknowledged as one of the world's great gastronomic marriages.

5. Dry

“Dry” refers to the amount of residual sugar left in a beer following fermentation. This type of beer is fermented for longer than normal brews so that practically all of the residual sugar is converted into alcohol. The result is a beer which consumers describe as having a crisp flavour, clean finish and very little aftertaste.

The word lager is derived from the German verb “lagern”, which means: to store. During the late middle ages, before the days of refrigeration, fermentation was a hit-or-miss affair, especially during the hot summer months. To ensure a supply of beer for the summer, brewers in the Bavarian Alps stored kegs of spring brew in icy mountain caves. As the beer slowly aged, the yeast settled, creating a drink that was dark but clear and sparkling with a crisper, more delicate flavour. In 1842, lager acquired its familiar golden colour when a brewery in Pilsen, Czechoslovakia perfected a pale, bottom-fermented version of the beer. Lagers typically take more time to brew and are aged longer than ales. Lagers are best enjoyed at cooler-than-room temperature.

2. Bock Beer

The other bottom-fermented beer is bock, named for the famous medieval German brewing town of Einbeck. Heavier than lager and darkened by high-coloured malts, bock is traditionally brewed in the winter for drinking during the spring.

3. Ale

Although the term covers a fascinating variety of styles, all ales share certain characteristics. Top-fermentation and the inclusion of more hops in the wort give these beers a distinctive fruitiness, acidity and a pleasantly-bitter seasoning. All ales typically take less time to brew and age then lagers and have a more assertive, individual personality, though their alcoholic strength may be the same. Ales are best enjoyed at room temperature or slightly warmer.

4. Porter and Stout

Whether dry or sweet, flavoured with roasted malt barley, oats or certain sugars, stouts and porters are characterized by darkness and depth. Both types of beer are delicious with hearty meat stews and surprisingly good with shellfish. The pairing of oysters and stout has long been acknowledged as one of the world's great gastronomic marriages.

5. Dry

“Dry” refers to the amount of residual sugar left in a beer following fermentation. This type of beer is fermented for longer than normal brews so that practically all of the residual sugar is converted into alcohol. The result is a beer which consumers describe as having a crisp flavour, clean finish and very little aftertaste.

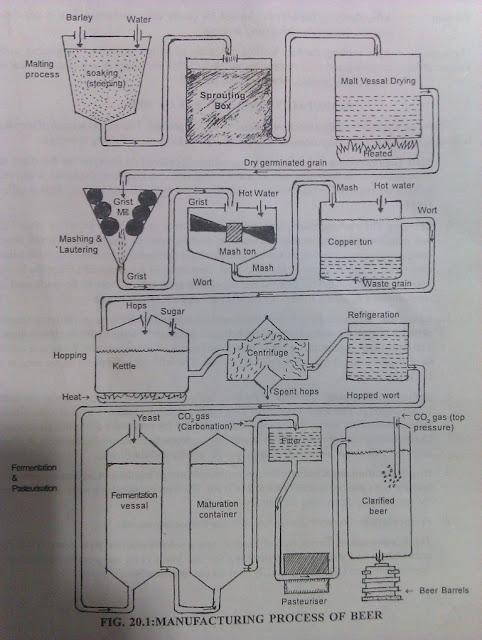

IV. MANUFACTURING

Brewing is fundamentally a natural process. The art and science of brewing lies in converting natural food materials into a pure, pleasing beverage. Although great strides have been made with the techniques for achieving high-quality production, beer today is still a beverage brewed from natural products in a traditional way.

Although the main ingredients of beer have remained constant (water, yeast, malt and hops), it is the precise recipe and timing of the brew that gives one a different taste from another. The production of beer is one of the most closely supervised and controlled manufacturing processes in our society. Apart from brewing company expenditures on research and quality control designed to achieve the highest

standards of uniformity and purity in the product, the production of beer is also subject to regular inspection and review by federal and provincial Health Departments. Substances used in the brewing process are approved by Health Canada. On average, a batch of beer will take about 30 days to produce. To be more specific, brewing takes nine and a half hours, while fermentation and aging combined take between 21 and 35 days for ales and lagers respectively.

1. Malt

Barley is used to make brewers' malt. At the malting companies, barley is soaked, germinated (sprouted-the germinated barley is known as green malt), then dried and/or kilned/roasted to arrest further growth. During the period of controlled growth in the malting plant, specific barley enzymes (diastaise) are released to break down the membranes of the starch cells that make up most of the kernel. But these are internal changes only; apart from a slight change in colour, the external characteristics remain essentially unchanged. When the malt leaves a malting plant, it still looks like barley.

In the brewery, the malt is screened and crushed (crushed malt is known as grist) rather than ground to flour in order to keep the husks as whole as possible. This process not only prevents the extraction of undesirable materials from the husks but also allows them to act as a filter bed for separation of the liquid extract formed during mashing.

2. Mashing

Malt is added to heated, purified water and, through a carefully controlled time and temperature process, the malt enzymes break down the starch to sugar and the complex proteins of the malt to simpler nitrogen compounds. Mashing takes place in a large, round tank called a "mash mixer" or "mash tun" and requires careful temperature control. At this point, depending on the type of beer desired, the malt is supplemented by starch from other cereals such as corn, wheat or rice.

3. Lautering

The mash is transferred to a straining (or lautering) vessel which is usually cylindrical with a slotted false bottom two to five centimeters above the true bottom. The liquid extract drains through the false bottom and is run off to the brew kettle. This extract, a sugar solution, is called "wort" but it is not yet beer. Water is "sparged" (or sprayed) though the grains to wash out as much of the extract as possible. The "spent grains" are removed and sold as cattle feed.

4. Boiling and Hopping

The brew kettle, a huge cauldron holding from 70 to 1,000 hectoliters and made of shiny copper or stainless steel, is probably the most striking sight in a brewery. It is fitted with coils or a jacketed bottom for steam heating and is designed to boil the wort under carefully-controlled conditions. Boiling, which usually lasts about two hours, serves to concentrate the wort to a desired specific gravity, to sterilize it and to obtain the desired extract from the hops. The hop resins contribute flavour, aroma and bitterness to the brew. Once the hops have flavoured the brew, they are removed. When applicable, highly-fermentable syrup may be added to the kettle. Undesirable protein substances that have survived the journey from the mash mixer are coagulated, leaving the wort clear.

5. Hop Separation and Cooling

After the beer has taken on the flavour of the hops, the wort then proceeds to the "hot wort tank". It is then cooled, usually in a simple-looking apparatus called a "plate cooler". As the wort and a coolant flow past each other on opposite sides of stainless steel plates, the temperature of the wort drops from boiling to about 10 to 15.5 °C, a drop of more than 65.6 °C, in a few seconds.

6. Fermentation

The wort is then moved to the fermenting vessels and yeast, the guarded central mystery of ancient brewer's art, is added. It is the yeast, which is a living, single cell fungi, that breaks down the sugar in the wort to carbon dioxide and alcohol. It also adds many beer-flavouring components. There are many kinds of yeasts, but those used in making beer belong to the genus saccharomyces. The brewer uses

two species of this genus. One yeast type, which rises to the top of the liquid at the completion of the fermentation process, is used in brewing ale and stout. The other, which drops to the bottom of the brewing vessel, is used in brewing lager. In all modern breweries, elaborate precautions are taken to ensure that the yeast remains pure and unchanged. Through the use of pure yeast culture plants, a particular beer flavour can be maintained year after year. During fermentation, which lasts about seven to 10 days, the yeast may multiply six-fold and in the open-tank fermenters used for brewing ale, a creamy, frothy head may be seen on top of the brew. When the fermentation is complete, the yeast is removed. Now, for the first time, the liquid is called beer.

7. Cellars

For one to three weeks, the beer is stored cold and then filtered once or twice before it is ready for bottling or "racking" into kegs.

8. Packaging

In the bottle shop of a brewery, returned empty bottles go through washers in which they receive a thorough cleaning. After washing, the bottles are inspected electronically and visually and pass on to the rotary filler. Some of these machines can fill up to 1,200 bottles per minute. A "crowning" machine, integrated with the filler, places caps on the bottles.

Although the main ingredients of beer have remained constant (water, yeast, malt and hops), it is the precise recipe and timing of the brew that gives one a different taste from another. The production of beer is one of the most closely supervised and controlled manufacturing processes in our society. Apart from brewing company expenditures on research and quality control designed to achieve the highest

standards of uniformity and purity in the product, the production of beer is also subject to regular inspection and review by federal and provincial Health Departments. Substances used in the brewing process are approved by Health Canada. On average, a batch of beer will take about 30 days to produce. To be more specific, brewing takes nine and a half hours, while fermentation and aging combined take between 21 and 35 days for ales and lagers respectively.

1. Malt

Barley is used to make brewers' malt. At the malting companies, barley is soaked, germinated (sprouted-the germinated barley is known as green malt), then dried and/or kilned/roasted to arrest further growth. During the period of controlled growth in the malting plant, specific barley enzymes (diastaise) are released to break down the membranes of the starch cells that make up most of the kernel. But these are internal changes only; apart from a slight change in colour, the external characteristics remain essentially unchanged. When the malt leaves a malting plant, it still looks like barley.

In the brewery, the malt is screened and crushed (crushed malt is known as grist) rather than ground to flour in order to keep the husks as whole as possible. This process not only prevents the extraction of undesirable materials from the husks but also allows them to act as a filter bed for separation of the liquid extract formed during mashing.

2. Mashing

Malt is added to heated, purified water and, through a carefully controlled time and temperature process, the malt enzymes break down the starch to sugar and the complex proteins of the malt to simpler nitrogen compounds. Mashing takes place in a large, round tank called a "mash mixer" or "mash tun" and requires careful temperature control. At this point, depending on the type of beer desired, the malt is supplemented by starch from other cereals such as corn, wheat or rice.

3. Lautering

The mash is transferred to a straining (or lautering) vessel which is usually cylindrical with a slotted false bottom two to five centimeters above the true bottom. The liquid extract drains through the false bottom and is run off to the brew kettle. This extract, a sugar solution, is called "wort" but it is not yet beer. Water is "sparged" (or sprayed) though the grains to wash out as much of the extract as possible. The "spent grains" are removed and sold as cattle feed.

4. Boiling and Hopping

The brew kettle, a huge cauldron holding from 70 to 1,000 hectoliters and made of shiny copper or stainless steel, is probably the most striking sight in a brewery. It is fitted with coils or a jacketed bottom for steam heating and is designed to boil the wort under carefully-controlled conditions. Boiling, which usually lasts about two hours, serves to concentrate the wort to a desired specific gravity, to sterilize it and to obtain the desired extract from the hops. The hop resins contribute flavour, aroma and bitterness to the brew. Once the hops have flavoured the brew, they are removed. When applicable, highly-fermentable syrup may be added to the kettle. Undesirable protein substances that have survived the journey from the mash mixer are coagulated, leaving the wort clear.

5. Hop Separation and Cooling

After the beer has taken on the flavour of the hops, the wort then proceeds to the "hot wort tank". It is then cooled, usually in a simple-looking apparatus called a "plate cooler". As the wort and a coolant flow past each other on opposite sides of stainless steel plates, the temperature of the wort drops from boiling to about 10 to 15.5 °C, a drop of more than 65.6 °C, in a few seconds.

6. Fermentation

The wort is then moved to the fermenting vessels and yeast, the guarded central mystery of ancient brewer's art, is added. It is the yeast, which is a living, single cell fungi, that breaks down the sugar in the wort to carbon dioxide and alcohol. It also adds many beer-flavouring components. There are many kinds of yeasts, but those used in making beer belong to the genus saccharomyces. The brewer uses

two species of this genus. One yeast type, which rises to the top of the liquid at the completion of the fermentation process, is used in brewing ale and stout. The other, which drops to the bottom of the brewing vessel, is used in brewing lager. In all modern breweries, elaborate precautions are taken to ensure that the yeast remains pure and unchanged. Through the use of pure yeast culture plants, a particular beer flavour can be maintained year after year. During fermentation, which lasts about seven to 10 days, the yeast may multiply six-fold and in the open-tank fermenters used for brewing ale, a creamy, frothy head may be seen on top of the brew. When the fermentation is complete, the yeast is removed. Now, for the first time, the liquid is called beer.

7. Cellars

For one to three weeks, the beer is stored cold and then filtered once or twice before it is ready for bottling or "racking" into kegs.

8. Packaging

In the bottle shop of a brewery, returned empty bottles go through washers in which they receive a thorough cleaning. After washing, the bottles are inspected electronically and visually and pass on to the rotary filler. Some of these machines can fill up to 1,200 bottles per minute. A "crowning" machine, integrated with the filler, places caps on the bottles.

9. Pasteurization

The filled bottles may then pass through a "tunnel pasteurizer" (often 23 meters’ from end to end and able to hold 15,000 bottles) where the temperature of the beer is raised about 60 °C. For a sufficient length of time to provide biological stability, then cooled to room temperature.

Emerging from the pasteurizer, the bottles are inspected, labeled, placed in boxes, stacked on pallets and carried by lift truck to the warehousing areas to await shipment. Also in the bottle shop may be the canning lines, where beer is packaged in cans for shipment. Packaged beer may be heat-pasteurized or micro filtered, providing a shelf-life of up to six months when properly stored. Draught beer, since it is normally sold and consumed within a few weeks, may not go through this process. The draught beer is placed in sterilized kegs ready for shipment.

|

| beer manufacturing process |

Draught bear

Draught beer (also called draft beer or tap beer) has several related though slightly different understandings. The majority of references to draught beer are of filtered beer that has been served from a pressurised container, such as a keg or a widget can. A wider meaning of beer that is served from a keg (or tap), but not from a can, bottle or cask, is also used. A more traditional definition is beer that is served from a large container, which could be either a keg or a cask. The different understandings may at times overlap and cause confusion. Some traditionalists object to the more modern use of the word when applied to canned beer. The slight usage differences of the term is due to the history and development of beer dispensing.

Beer dispensing system

Parts

Gas cylinder

Gas plant (pressure reduction, control gauges, etc)

Keg/cask (often a bank of several connected kegs)

Extractor of coupler (to connect the keg to the beer line)

Beer line

Cooler

Tap (or gum)

Not all systems are exactly the same. Different breweries use the different systems, and changes are made from time to time to improve them.

Different capacities of casks

some facts

Beer dispensing system

Parts

Gas cylinder

Gas plant (pressure reduction, control gauges, etc)

Keg/cask (often a bank of several connected kegs)

Extractor of coupler (to connect the keg to the beer line)

Beer line

Cooler

Tap (or gum)

Not all systems are exactly the same. Different breweries use the different systems, and changes are made from time to time to improve them.

|

| draught beer serving process |

Different capacities of casks

some facts

- Degree of roasting the malt determines the colour of the beer.

- Pale malt is for ale and dark malt is for dark beers and stout

- Top fermentation occurs at higher temperature 15-25 degree celcius and bottom fermentation occurs at lower temperature 5-9 degree celcius.

- Beer with high alcoholic content (8-11%) is termed as barley wine.

- Ales are served at 12-14 degree celcius and lagers at 7-10 degree celcius.

- The place where beer is produced is known as brewery.

- Some pubs produce their own beers and these are known as brewpubs.

- Bottle conditioned beers are termed as sediment beers.

- The Czech republican is well known for lager and UK for ale

- Ale is top fermented and lager is bottom fermented.

Beer additives-

beer additives are synthetic products that may or may not be added in beer to expedite a number of functions such as-

• Conversion of starch to sugar

• Adjust the final colour of the product

• To prevent the cloudiness

• To stabilize the head or collar of the beer

• To prolong the shelf life of the beer

These products may change the taste of natural beer. A few examples are-

• Gum Arabic- helps to stabilize the head

• Hydroxyl benzoate- acts as a preservative

• EDTA- ethelene diamine tetra benzoate- prevents gushing out of the beer

• Ascorbic acid- acts as antioxidant.

Nutritive value of beer

Protein 1.6-1.7g

Fat 0.0gm

Carbohydrate 15.9gm

Water 92%

Ethyl alcohol 3.8%, variable

Solid and extracts 4.2%

Faults in beer

Beer faults can be attributed to poor cellar management Following are the common reasons for the poor quality of beer.

• Dirty beer dispensing system

• Failure to clean the beer lines with water after every empty barrel

• Failure to draw off the beer left in pipes after the operations ' Failure to leave water in the beer lines overnight

• Poor sanitary conditions of the bar » Warm temperature

• Greasy glasses

• High fluctuations in the temperature Common faults noticed in the beer and the possible reasons for them are in the following.

Sour beer

• Deposits of ycasv m xhc pipes and dispensing equipment

• &ddmg stale beer to a firesh cask of beer

• Not exhausting the beer on time

• Exposing the beer to heavy fluctuations of temperature

• Exposed to heavy lighting

Cloudy beer

• Stored in low temperature

• Uncleaned or poorly cleaned pipes

• Trying to pull the beer from the cask before removing the spile Flat beer

• Poor or faulty spile control—having a soft pile when hard spile

• Too low a temperature

• Served in a greasy glass

• Poured and left in the glass for a long time

Foreign bodies

• Production error

• Dirty beer dispensing system

• Failure to clean the beer lines with water after every empty barrel

• Failure to draw off the beer left in pipes after the operations ' Failure to leave water in the beer lines overnight

• Poor sanitary conditions of the bar » Warm temperature

• Greasy glasses

• High fluctuations in the temperature Common faults noticed in the beer and the possible reasons for them are in the following.

Sour beer

• Deposits of ycasv m xhc pipes and dispensing equipment

• &ddmg stale beer to a firesh cask of beer

• Not exhausting the beer on time

• Exposing the beer to heavy fluctuations of temperature

• Exposed to heavy lighting

Cloudy beer

• Stored in low temperature

• Uncleaned or poorly cleaned pipes

• Trying to pull the beer from the cask before removing the spile Flat beer

• Poor or faulty spile control—having a soft pile when hard spile

• Too low a temperature

• Served in a greasy glass

• Poured and left in the glass for a long time

Foreign bodies

• Production error

Storage of beer

Following are the ways for beer storage.

• Beer must be stored in a well-ventilated cellar at the temperature range of 13-15°C (55-58°F).

• The casks received should be kept on the stillions and should remain at least for 24 hours to allow it to settle after its journey from the brewery.

• Spile control should be done carefully to ensure the quality of the beer and control the pressure inside the cask.

• Tapping should be carried out 24 hours before it is required.

• Beer left in the pipe at the end of the day should be drawn off and filtered back into its cask.

• High temperature fluctuations will spoil the beer and it must be avoided.

• Bottled beers should be stored in clean conditions and must not be subjected to extremes of temperatures. Beer stored at too cold temperature will develop a 'chill haze'. It may disappear, if the temperature reaches about 7°C (45°F).

• Bottled beers should not be exposed to sun light. The shelf life of the bottled beers varies. Brown ale has a shelf life of about three weeks, light ale, about six weeks, stout lagers, and nips of strong ales can be stored for six months in ideal conditions. Bottles displayed on the bar j should be wiped clean, and arranged in a way that their labels face the guests.

• Adequate quantity of beer bottles of each brand should be stored in the cooler and replaced when the stock moves.

• Beer must be stored in a well-ventilated cellar at the temperature range of 13-15°C (55-58°F).

• The casks received should be kept on the stillions and should remain at least for 24 hours to allow it to settle after its journey from the brewery.

• Spile control should be done carefully to ensure the quality of the beer and control the pressure inside the cask.

• Tapping should be carried out 24 hours before it is required.

• Beer left in the pipe at the end of the day should be drawn off and filtered back into its cask.

• High temperature fluctuations will spoil the beer and it must be avoided.

• Bottled beers should be stored in clean conditions and must not be subjected to extremes of temperatures. Beer stored at too cold temperature will develop a 'chill haze'. It may disappear, if the temperature reaches about 7°C (45°F).

• Bottled beers should not be exposed to sun light. The shelf life of the bottled beers varies. Brown ale has a shelf life of about three weeks, light ale, about six weeks, stout lagers, and nips of strong ales can be stored for six months in ideal conditions. Bottles displayed on the bar j should be wiped clean, and arranged in a way that their labels face the guests.

• Adequate quantity of beer bottles of each brand should be stored in the cooler and replaced when the stock moves.

III.BEER GLOSSARY

This is a list of terms used when describing beers:

Abbey

Commercial Belgian beers licensed by abbeys. Not to be confused with Trappist ales.

Adjuncts

Materials, like rice, corn and brewing sugar, used in place of traditional grains for cheapness

or lightness of flavor.

Ale

The oldest beer style in the world. Produced by warm or top fermentation.

Alt

Dark brown top-fermenting beer from Düsseldorf.

Alpha acid

The main component of the bittering agent in the hop flower.

Attenuation

The extent to which brewing sugars turn to alcohol and carbon dioxide.

Kölsch

Top-fermenting golden beer from Cologne.

Kräusen

The addition of partially-fermented wort during lagering to encourage a strong secondary fermentation.

Kriek

Cherry-flavored lambic beer.

Lager

The cold-conditioning of beer at around 0 degrees Centigrade to encourage the yeast to

settle out, increase carbonation and produce a smooth, clean-tasting beer. From the German

meaning "to store".

Lambic

Belgian beer made by spontaneous fermentation.

Lauter tun

Vessel used to clarify the wort after the mashing stage.

Beer

Generic term for an alcoholic drink made from grain. Includes both ale and lager.

Bitter

British term for the pale, amber or coppercolored beers that developed from the pale ales in the 19th century.

Bock or Bok

Strong beer style of The Netherlands and Germany.

Bottle-conditioned

Beer that undergoes a secondary fermentation in the bottle.

Brew kettle

See Copper

Cask-conditioned

Beer that undergoes a secondary fermentation in the cask. Known as "real ale", closely identified with British beers.

Copper

Vessel used to boil the sugary wort with hops.

Decoction mashing

A system mainly used in lager brewing in which portions of the wort are removed from the vessel, heated to a higher temperature and then returned. Improves ensymic activity and the conversion of starch to sugar in poorly modified malts.

Malt

Barley or other cereals that have been partially germinated to allow starches to be converted

into fermentable sugars.

Mash

First stage of the brewing process, when the malt is mixed with pure hot water to extract the

sugars.

Märzen

Traditional Bavarian lager brewed in March and stored until autumn for the Munich Oktoberfest.

Mild

Dark brown (occasionally pale) English and Welsh beer, lightly hopped. The oldest style of

beer that once derived it color from malt cured over wood fires. One of the components of the

first porters.

Milk stout

Stout made with the addition of lactose, which is unfermentable, producing a beer low in alcohol with a creamy, slightly sweet character.

Pilsner or Pilsener or Pils

International brand name for a light-colored lager.

Porter

Dark - brown or black - beer originating in London.

Priming

Addition of sugar to encourage a secondary fermentation in beer.

Dry-hopping

The addition of a small amount of hops to a cask of beer to improve aroma and bitterness.

Dunkel

A dark lager beer in Germany, a Bavarian speciality that predates the first pale lagers.

Entire

The earliest form of porter, short for "entire butt".

Ester

Flavor compounds produced by the action of yeast turning sugars into alcohol and carbon dioxide. Esters may be fruity or spicy.

Fining

Substance that clarifies beer, usually made from the swim bladder of sturgeon fish; also known

as isinglass.

Framboise or Frambozen

Raspberry-flavored lambic beer.

Grist

The coarse powder derived from malt that has been milled or "cracked" in the brewery prior to mashing.

Gueuze

A blend of Belgian lambic beers.

Reinheitsgebot

Bavarian beer law of 1516 (the "Purity Pledge) that lays down that only malted grain, hops, yeast and water can be used in brewing. Now covers the whole of Germany.

Shilling

Ancient method of invoicing beer in Scotland on strength. Beers are called 60, 70 or 80 shilling.

Sparging

From the French esparger, to sprinkle; Sprinkling or spraying the spent grains in the mash tun or lauter tun to flush out any remaining malt sugars.

Square

A traditional, open fermenting vessel.

Steam beer

American beer style saved by the Anchor Brewery in San Francisco.

Stout

Once an English generic term for the strongest ("stoutest") beer in a brewery. Now considered

a quintessentially Irish style.

Trappist

Ales brewed by monks of the Trappist order in Belgium and The Netherlands.

Union

Method of fermentation developed in Burton-tn- Trent using large oak casks.

Helles or Hell

A pale Bavarian lager beer.

Hop (Lat: Humulus Lupulus)

Herb used when brewing to add aroma and bitterness.

IBU

International Bitterness Units. An internationally-agreed scale for measuring the bitterness of beer. A "lite" American lager may have around 10 IBU's, an English mild ale around 20 units, an India Pale Ale 40 or higher, an Irish stout 55 to 60 and barley wine 65.

Infusion

Method of mashing used mainly in ale-brewing where the grains are left to soak with pure

water while starches convert to sugar, usually carried out at a constant temperature.

Ur or Urtyp

German for original.

Weizen or Weisse

German for wheat or white beer.

Wort

Liquid resulting from the mashing process, rich in malt and sugars.

Chill haze

It is the cloudy appearance of beer due to storing in very cold temperature.

Head

In beer service, it refers to foam that is created while serving due to the presence of C02.

Pitching It means adding yeast.

Sparging

Spraying with hot water to extract maximum sugar from malt.

Spile

It is a wooden peg used as a stopper or plug. Hard spile is used to retain the gas inside the cask and the soft to allow the gas to escape

Stillions

It is a frame, stand, rack, or platform for storing the casks off the floor in the cellar.

Abbey

Commercial Belgian beers licensed by abbeys. Not to be confused with Trappist ales.

Adjuncts

Materials, like rice, corn and brewing sugar, used in place of traditional grains for cheapness

or lightness of flavor.

Ale

The oldest beer style in the world. Produced by warm or top fermentation.

Alt

Dark brown top-fermenting beer from Düsseldorf.

Alpha acid

The main component of the bittering agent in the hop flower.

Attenuation

The extent to which brewing sugars turn to alcohol and carbon dioxide.

Kölsch

Top-fermenting golden beer from Cologne.

Kräusen

The addition of partially-fermented wort during lagering to encourage a strong secondary fermentation.

Kriek

Cherry-flavored lambic beer.

Lager

The cold-conditioning of beer at around 0 degrees Centigrade to encourage the yeast to

settle out, increase carbonation and produce a smooth, clean-tasting beer. From the German

meaning "to store".

Lambic

Belgian beer made by spontaneous fermentation.

Lauter tun

Vessel used to clarify the wort after the mashing stage.

Beer

Generic term for an alcoholic drink made from grain. Includes both ale and lager.

Bitter

British term for the pale, amber or coppercolored beers that developed from the pale ales in the 19th century.

Bock or Bok

Strong beer style of The Netherlands and Germany.

Bottle-conditioned

Beer that undergoes a secondary fermentation in the bottle.

Brew kettle

See Copper

Cask-conditioned

Beer that undergoes a secondary fermentation in the cask. Known as "real ale", closely identified with British beers.

Copper

Vessel used to boil the sugary wort with hops.

Decoction mashing

A system mainly used in lager brewing in which portions of the wort are removed from the vessel, heated to a higher temperature and then returned. Improves ensymic activity and the conversion of starch to sugar in poorly modified malts.

Malt

Barley or other cereals that have been partially germinated to allow starches to be converted

into fermentable sugars.

Mash

First stage of the brewing process, when the malt is mixed with pure hot water to extract the

sugars.

Märzen

Traditional Bavarian lager brewed in March and stored until autumn for the Munich Oktoberfest.

Mild

Dark brown (occasionally pale) English and Welsh beer, lightly hopped. The oldest style of

beer that once derived it color from malt cured over wood fires. One of the components of the

first porters.

Milk stout

Stout made with the addition of lactose, which is unfermentable, producing a beer low in alcohol with a creamy, slightly sweet character.

Pilsner or Pilsener or Pils

International brand name for a light-colored lager.

Porter

Dark - brown or black - beer originating in London.

Priming

Addition of sugar to encourage a secondary fermentation in beer.

Dry-hopping

The addition of a small amount of hops to a cask of beer to improve aroma and bitterness.

Dunkel

A dark lager beer in Germany, a Bavarian speciality that predates the first pale lagers.

Entire

The earliest form of porter, short for "entire butt".

Ester

Flavor compounds produced by the action of yeast turning sugars into alcohol and carbon dioxide. Esters may be fruity or spicy.

Fining

Substance that clarifies beer, usually made from the swim bladder of sturgeon fish; also known

as isinglass.

Framboise or Frambozen

Raspberry-flavored lambic beer.

Grist

The coarse powder derived from malt that has been milled or "cracked" in the brewery prior to mashing.

Gueuze

A blend of Belgian lambic beers.

Reinheitsgebot

Bavarian beer law of 1516 (the "Purity Pledge) that lays down that only malted grain, hops, yeast and water can be used in brewing. Now covers the whole of Germany.

Shilling

Ancient method of invoicing beer in Scotland on strength. Beers are called 60, 70 or 80 shilling.

Sparging

From the French esparger, to sprinkle; Sprinkling or spraying the spent grains in the mash tun or lauter tun to flush out any remaining malt sugars.

Square

A traditional, open fermenting vessel.

Steam beer

American beer style saved by the Anchor Brewery in San Francisco.

Stout

Once an English generic term for the strongest ("stoutest") beer in a brewery. Now considered

a quintessentially Irish style.

Trappist

Ales brewed by monks of the Trappist order in Belgium and The Netherlands.

Union

Method of fermentation developed in Burton-tn- Trent using large oak casks.

Helles or Hell

A pale Bavarian lager beer.

Hop (Lat: Humulus Lupulus)

Herb used when brewing to add aroma and bitterness.

IBU

International Bitterness Units. An internationally-agreed scale for measuring the bitterness of beer. A "lite" American lager may have around 10 IBU's, an English mild ale around 20 units, an India Pale Ale 40 or higher, an Irish stout 55 to 60 and barley wine 65.

Infusion

Method of mashing used mainly in ale-brewing where the grains are left to soak with pure

water while starches convert to sugar, usually carried out at a constant temperature.

Ur or Urtyp

German for original.

Weizen or Weisse

German for wheat or white beer.

Wort

Liquid resulting from the mashing process, rich in malt and sugars.

Chill haze

It is the cloudy appearance of beer due to storing in very cold temperature.

Head

In beer service, it refers to foam that is created while serving due to the presence of C02.

Pitching It means adding yeast.

Sparging

Spraying with hot water to extract maximum sugar from malt.

Spile

It is a wooden peg used as a stopper or plug. Hard spile is used to retain the gas inside the cask and the soft to allow the gas to escape

Stillions

It is a frame, stand, rack, or platform for storing the casks off the floor in the cellar.

It's essential to read this post and thanks for sharing this helpful post. If anyone has a problem in your life contact us we give the solution to your problem.S brewing Manufacturer of microbrewery equipment

ReplyDeleteThis info is very helpful for everyone. Keep it up customer relationship management module in erp

ReplyDelete